Alloy Multimet N155 (AMS 5532 / AMS 5769)

ʻO kā mākou limahana ma o ka hoʻomaʻamaʻa ʻoihana.ʻIke ʻoihana akamai, manaʻo paʻa o ka lawelawe, e hoʻokō i nā koi lawelawe o nā mea kūʻai aku no AlloyMultimet N155(AMS 5532 / AMS 5769), Ma ke ʻano he alakaʻi alakaʻi a me ka mea kūʻai aku, hauʻoli mākou i kahi moʻolelo mele maikaʻi loa i loko o nā mākeke honua, ʻoi aku hoʻi ma ʻAmelika a me ʻEulopa, no ka maikaʻi a me nā kumukūʻai ʻae ʻia.

ʻO kā mākou limahana ma o ka hoʻomaʻamaʻa ʻoihana.ʻO ka ʻike ʻoihana akamai, ka manaʻo paʻa o ka lawelawe, e hoʻokō i nā koi lawelawe o nā mea kūʻai akuHuina N155, Multimet N155, UNS R30155, E ʻoluʻolu e ʻoluʻolu e hoʻouna mai iā mākou i kāu mau kikoʻī a e pane mākou iā ʻoe asap.Loaʻa iā mākou kahi hui ʻenehana loea e lawelawe no kēlā me kēia pono kikoʻī.Hiki ke hoʻouna ʻia nā laʻana manuahi iā ʻoe iho e ʻike i nā mea ʻike hou aku.I hiki iā ʻoe ke hoʻokō i kāu mau makemake, e ʻoluʻolu e ʻoluʻolu e hoʻokaʻaʻike mai iā mākou.Hiki iā ʻoe ke hoʻouna mai iā mākou i nā leka uila a kelepona pololei iā mākou.Eia hou, mahalo mākou i nā kipa ʻana i kā mākou hale hana mai nā wahi a pau o ka honua no ka ʻike maikaʻi ʻana i kā mākou hui.nd kuai.I kā mākou kālepa me nā mea kālepa o nā ʻāina he nui, pili pinepine mākou i ke kumu o ka kaulike a me ka pono like.ʻO ko mākou manaʻolana e kūʻai aku, ma o ka hoʻoikaika pū ʻana, i ke kālepa a me ka hoaloha i ko mākou pono like.Manaʻo mākou i ka loaʻa ʻana o kāu mau nīnau.

Nā inoa kālepa maʻamau:Huina N155, Multimet N155, R30155 , W.Nr 1.4974

Huina N155ʻO ia ka Nickel-Chromium-Cobalt alloy me nā mea hoʻohui o Molybdenum a me Tungsten i hoʻohana maʻamau i nā ʻāpana e koi ana i ka ikaika kiʻekiʻe a hiki i 1350 ° F a me ke kūpaʻa oxidation a hiki i 1800 ° F.ʻO kona mau mea wela kiʻekiʻe i loko o ke kūlana i hoʻolako ʻia (ka hopena i mālama ʻia ma 2150 ° F) a ʻaʻole hilinaʻi i ka paʻakikī makahiki.Hoʻohana ʻia ʻo Multimet N155 i ka nui o nā noi aerospace e like me nā tailpipes a me nā cones huelo, nā lau turbine, nā shafts a me nā rotors, nā ʻāpana afterburner a me nā bolts wela kiʻekiʻe.

Huihui N155 Kemimi

| Alloy | % | C | Si | Fe | Mn | P | S | Cr | Ni | Co | Mo | W | Nb | Cu | N |

| N155 | Min. | 0.08 | bal | 1.0 | 20.0 | 19.0 | 18.5 | 2.5 | 2.0 | 0.75 | 0.1 | ||||

| Max. | 0.16 | 1.0 | 2.0 | 0.04 | 0.03 | 22.5 | 21.0 | 21.0 | 3.5 | 3.0 | 1.25 | 0.5 | 0.2 |

Alloy N155 Nā Pono Kino

| ʻO ka mānoanoa | 8.25 g/cm³ |

| Lae hehee | 2450 ℃ |

Alloy N155 Mechanical Pono

| Kūlana | Ka ikaika tensile Rm N/mm² | Hua ikaika Rp 0. 2N/mm² | ʻO ka lōʻihi E like me % | ʻO Brinell paʻakikī HB |

| Lapaʻau hoʻonā | 690-965 | 345 | 20 | 82-92 |

Alloy N155 Nā Kūlana a me nā kikoʻī

AMS 5532 ,AMS 5769 ,AMS 5794,AMS 5795

| Hoʻopaʻa ʻana i ka lāʻau | Uea | Hoʻopaʻa / ʻāwili | Pepa/Pula |

| AMS 5769 | AMS 5794 | AMS 5532 | AMS 5532 |

ʻO Alloy N155 nā huahana i loaʻa ma Sekonic Metals

Alloy N155 kaola a me na kookoo

ʻO nā kaola pōʻai / nā pā pālahalaha / nā kī Hex, Nui mai 8.0mm-320mm, Hoʻohana ʻia no nā bolts, fastners a me nā ʻāpana ʻokoʻa ʻē aʻe.

Alloy N155 welding wire & Spring wire

Hoʻolako ʻia ma ka uea kuʻi a me ka uea puna ma ke ʻano coil a ʻoki ʻia ka lōʻihi.

Alloy N155 pepa a me ka pā

ʻO ka laulā a hiki i 1500mm a me ka lōʻihi a hiki i 6000mm, Mānoanoa mai 0.1mm a 100mm.

Alloy N155 apo apo

Forging Ring a i ʻole gasket, hiki ke hoʻopili ʻia ka nui me ka ʻālohilohi a me ka hoʻomanawanui pololei

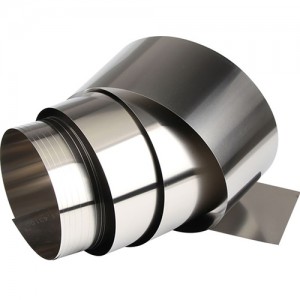

Alloy N155 strip & coil

ʻO ke kūlana palupalu a me ke kūlana paʻakikī me ka ʻili ʻālohilohi AB, ka laulā a hiki i 1000mm

No ke aha ʻo Alloy N155?

Loaʻa i ka Alloy N155 ke kūpaʻa maikaʻi i ka corrosion i kekahi mau media ma lalo o nā kūlana oxidizing a hoʻemi.Ke mālama ʻia ka wela, ua like ke kūpaʻa ʻana o ka alloy N155 i ka waikawa nitric me ke kila kila.ʻOi aku ka maikaʻi o ke kūpaʻa ma mua o ke kila kila i nā hopena nāwaliwali o ka waika hydrochloric.Kūʻē ʻo ia i nā konohiki a pau o ka sulfuric acid ma ka lumi wela.Hiki ke hoʻopili ʻia ka alloy, hana ʻia a hana ʻia e nā ʻano hana maʻamau.

Hiki ke hoʻopili ʻia ka alloy e nā ʻano arc a me nā kaʻina hana pale-weld.Loaʻa kēia alloy ma ke ʻano he pepa, strip, plate, wire, coated electrodes, billet stock and sane and investment castings.

Loaʻa iā ia ma ke ʻano o ka hoʻoheheʻe hou ʻana i kahi kemika i hōʻoia ʻia.Hoʻouna ʻia ka hapa nui o nā ʻano huila n155 i ka hopena i mālama ʻia i ka wela e hōʻoia i nā waiwai kūpono.Hāʻawi ʻia ka lau i kahi hoʻoponopono wela o 2150°F, no ka manawa e pili ana i ka mānoanoa o ka ʻāpana, a ukali ʻia e ka ea wikiwiki a i ʻole ke kinai wai.ʻO ka pahu pahu a me ka pā (1/4 in. a ʻoi aku ke kaumaha) ʻo ia ka hopena wela i mālama ʻia ma 2150°F a ukali ʻia e ke kinai wai.

Ua pilikia ʻo Alloy N155 mai ka mediocre oxidation resistance, kahi ʻano no ka wela o ka wahi i hoʻopili ʻia i ka wā wili, a me kahi puʻupuʻu ākea ākea o nā waiwai mechanical.

Sekonic Metals Technology Co., Ltd ISO 9001 qualified factory specialized in production of High Temperature Alloys and Anti-Corrosion Alloys like Titanium Alloys, Precsion Alloys (Invar 36, Kovar 4J29, Soft Magnetic Alloys,) Hastelloy Alloys, Haynes Alloys, Monel Alloys , Inconel Alloys, Incoloy Alloys Coblat Alloys(Haynes 25, Alloy 188, Stellite Alloys) ect Since1996.ma hope o ka loaʻa ʻana o ka kūleʻa nui ma ka mākeke Kina, ua hoʻonui mākou i kā mākou ʻoihana i ka honua holoʻokoʻa mai 2000All huahana i hana ʻia e like me nā kūlana kūpono a nānā pono ʻia ma mua o ka hoʻouna ʻana i kā mākou hale hana.E like me ka RoHS a me IS09001: 2008 maʻamau, ua hoʻolako ʻia kā mākou huahana i ka bar, rod, wire, plate, strip, sheet, pipe ano tube, a me nā ʻano ʻē aʻe i hoʻohana ʻia i nā kula he nui, e like me ka mokulele & aerospace, metallurgy, machinery. , kemika uila, ikehu, ikehu kiʻekiʻe, etc. e hilinaʻi mau kā mākou hui i ka ʻuhane: "ʻoi aku ka maikaʻi, ka mea kūʻai aku ma mua" a lawelawe no nā mea hoʻohana o ka home a me nā ʻāina ʻē.