ʻO Hastelloy Nickel Alloys |ʻO Hastelloy X ka pale ʻana i ka ʻino

ʻO Hastelloy Nickel Alloys | ʻO Hastelloy X ka pale ʻana i ka ʻino,

,

Nā inoa kālepa maʻamau:ʻO Hastelloy X,UNS N06002、GH3536、W.Nr.2.4665

ʻO Hastelloy XHe ʻano nickel base superalloy me ka hao kiʻekiʻe, ka mea i hoʻoikaika nui ʻia e ka hopena paʻa o ka chromium a me ka molybdenum.Loaʻa iā ia ka hana anti-metalization a me ka corrosion, ka hoʻomanawanui ʻana a me ka ikaika creep ma lalo o 900 ℃, ke anuanu maikaʻi a me ka hana wela a me ka hana welding.

Hoʻohana ʻia i ka hana ʻana i nā ʻāpana aero-engine combustion chamber a me nā ʻāpana wela kiʻekiʻe, ma lalo o 900 ℃ no ka manawa lōʻihi, ka mahana hana pōkole a hiki i 1080 ℃.

Hoʻohui ʻia ʻo Hastelloy X Chemical

| Alloy | C | Cr | Ni | Fe | Mo | W | Al | B | Co | Si | Mn | P | S |

| ʻO Hastelloy X | 0.05~0.15 | 20.5~23.5 | kaulike | 17.0~20.0 | 8.0~10.0 | 0.2~1.0 | ≤0.1 | ≤0.005 | 0.5-2.5 | ≤1.0 | ≤1.0 | ≤0.015 | ≤0.01 |

Hastelloy X Na Waiwai Kino

| ʻO ka mānoanoa | 8.3 g/cm³ |

| Lae hehee | 1260-1355 ℃ |

ʻO Hastelloy X Nā Pono Mechanical

| Kūlana | Ka ikaika tensile Rm N/mm² | Hua ikaika Rp 0. 2N/mm² | ʻO ka lōʻihi E like me % | ʻO Brinell paʻakikī HB |

| Lapaʻau hoʻonā | 690 | 275 | 30 | >241 |

Nā Kūlana a me nā kikoʻī o Hastelloy X

| Bar/Rod | Uea | Hoʻopaʻa / ʻāwili | Pepa/Pula | Paipu/Tube | Ke kalaiwa ana |

| ASTM B572ASME SB572AMS 5754 | AMS 5798 | ASTM B435ASME SB435AMS 5536 | ASTM B662, ASME SB662 ASTM B619, ASME SB619 ASTM B626 , ASME SB626AMS 5587 | AMS 5754 | |

Loaʻa nā huahana Hastelloy X ma Sekonic Metals

ʻO Hastelloy X Bars & Rods

ʻO nā kaola pōʻai / nā pā pālahalaha / nā kī Hex, Nui Mai 8.0mm-320mm, Hoʻohana ʻia no nā bolts, fastners a me nā ʻāpana ʻokoʻa ʻē aʻe.

Hastelloy X Wire

Hoʻolako ʻia ma ka uea kuʻi a me ka uea puna ma ke ʻano coil a ʻoki ʻia ka lōʻihi.

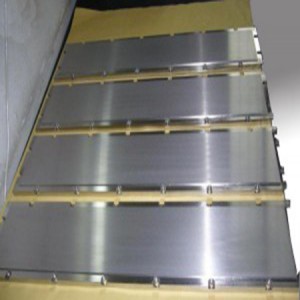

ʻO Hastelloy X pepa a me ka pā

ʻO ka laulā a hiki i 1500mm a me ka lōʻihi a hiki i 6000mm, Mānoanoa mai 0.1mm a 100mm.

ʻO Hastelloy X paipu ʻole a me ka paipu Welded

Hiki ke hana ʻia ka nui maʻamau a me ka nui i hoʻopili ʻia e mākou me ka hoʻomanawanui liʻiliʻi

ʻO Hastelloy X strip & coil

ʻO ke kūlana palupalu a me ke kūlana paʻakikī me ka ʻili ʻālohilohi AB, ka laulā a hiki i 1000mm

Hastelloy X Hoopaa

ʻO nā mea hana Hastelloy X i nā ʻano o Bolts, screws, flanges a me nā mea wikiwiki ʻē aʻe, e like me ka kikoʻī o nā mea kūʻai aku.

No ke aha ʻo Hastelloy X?

1. ʻOi aku ka maikaʻi o ka oxidation kū'ē i ke kiʻekiʻe wela (>1200 ℃)).

2. Ka ikaika wela kiʻekiʻe.

3. Good formability a weldability.

4. Ke kū'ē maikaʻi i ke koʻikoʻi corrosion māwae.

kahua noi Hastelloy X:

Ma muli o kona pale ʻana i ka corrosion ma nā ʻano lewa i ka wela kiʻekiʻe a me ka ikaika kiʻekiʻe kiʻekiʻe, ua hoʻohana nui ʻia ʻo HastelLoyx i nā ʻano wela wela.

Nā kahua noi maʻamau:

•ʻOihana a me nā mokulele mokulele (nā keʻena puhi ahi, nā mea hoʻoponopono, nā pāpale kūkulu)

•ʻO nā ʻāpana umu ahi ʻoihana, nā wili kākoʻo, nā pahu, nā lipine a me nā paipu radiator

•ʻO nā paipu spiral i nā kapuahi petrochemical

•Hoʻomaʻalili ke kinoea wela kiʻekiʻe i ka reactor nuklea

ʻO Hastelloy X kahi nickel base alloy nona ka ikaika kūʻokoʻa a me ka pale ʻana i ka oxidation a hiki i 2200 ° F.Ua ʻike ʻia ʻo ia ke kūpaʻa kūʻokoʻa i ka pohā ʻana i ke koʻikoʻi-corrosion i nā noi petrochemical.Loaʻa i ka alloy nā hiʻohiʻona maikaʻi loa i ka hoʻokumu ʻana a me ka welding.