Inconel602CA(UNS N06025) nickel-ferrochrome huila

Inconel602CA(UNS N06025) nickel-ferrochrome alloy,

ʻO Inconel602CA(UNS N06025) nickel-ferrochrome alloy Rod a me ka ipu hao ʻole.,

Nā inoa kālepa maʻamau: 602 CA;alloy602 СА;UNS N06025;W.Nr 2.4633

ʻO Inconel 602 CA alloy ka ʻoi loa o ka oxidation resistant/kiʻekiʻe ikaika nickel alloy i loaʻa.Hiki iā ia ke hoʻohana i ka wela wela a hiki i ka 2200°F (1200°C).No nā noi hoʻoponopono wela kahi e pono ai ka hoʻohaumia ʻana o ka huahana, makemake nui ʻia ka pale ʻana o ka oxidation/scaling o Inconel 602 CA.ʻO kahi maʻiʻo chromium kiʻekiʻe, me nā mea hoʻohui alumini a me yttrium, hiki i ka alloy ke hoʻomohala i kahi unahi oxide paʻa paʻa.

ʻO kahi maʻiʻo kalapona kiʻekiʻe i hui pū ʻia me nā mea hoʻohui i hoʻohui ʻia o ka titanium a me ka zirconium ka hopena i ka ikaika o ka haki ʻana.Hāʻawi ʻo Inconel 602 CA i ka 150% o ka ikaika o nā ʻāpana nickel i hoʻohana mau ʻia e like me ka alloy 600.

ʻO Inconel 602CA Ka Hui Kimia

| Alloy | % | Cr | Cu | Ni | P | S | Fe | C | Al | Ti | Y | Zr | Si | Mn |

| 602CA | Min. | 24.0 | - | kaulike | - | - | 8.0 | 0.15 | 1.8 | 0.1 | 0.05 | 0.01 | - | - |

| Max. | 26.0 | 0.1 | 0.02 | 0.01 | 11.0 | 0.25 | 2.4 | 0.2 | 0.12 | 0.1 | 0.5 | 0.15 |

Inconel 602CA mau waiwai kino

| ʻO ka mānoanoa | 0.285 lb/in3 |

| Lae hehee | 2350 – 2550°F |

Inconel 602CA Mechanical Waiwai

Na Waiwai Tensile Lunamakaainana

| Mahana, ° F | 68 | 1000 | 1500 | 1600 | 1800 | 2000 | 2200 |

| ʻO ka ikaika ʻoi loa, ksi | 105 | 93.4 | 41.2 | 32.8 | 17.1 | 13 | 5.8 |

| 0.2%Ka ikaika hua, ksi | 50.5 | 38.3 | 34.8 | 28.7 | 15.2 | 11.6 | 5.0 |

| Hooloihi, % | 38 | 43 | 78 | 82 | 78 | 85 | 96 |

ʻO nā mea kolo maʻamau

| Mahana, °F | 1400 | 1600 | 1800 | 1900 | 2000 | 2100 |

| Holoi liʻiliʻi 0.0001%/Hora, ksi | 9.4 | 2.4 | 0.96 | 0.59 | – | – |

| 10,000 Hour Rupture ikaika, ksi | 11.3 | 3.2 | 1.5 | 0.99 | 0.67 | 0.44 |

Inconel 602CA Nā Kūlana a me nā kikoʻī

ASME Code Case 2359, ASME SB 166, ASME SB 168, ASTM B 166, ASTM B 168, ERNiCrFe-12, UNS N06025, W. Nr./EN 2.4633

| Bar/Rod | Uea | Hoʻopaʻa / ʻāwili | Pepa/Pula |

| ASTM B166;ASME SB166 | ASTM B166;ASME SB166 | ASTM B168;ASME SB168 | ASTM B168;ASME SB168 |

ʻO Inconel 602CA nā huahana i loaʻa ma Sekonic Metals

ʻO Inconel 602CA nā pahu a me nā lāʻau

ʻO nā kaola pōʻai / nā pā pālahalaha / nā kī Hex, Nui mai 8.0mm-320mm, Hoʻohana ʻia no nā bolts, fastners a me nā ʻāpana ʻokoʻa ʻē aʻe.

Inconel 602CA welding wire & Spring wire

Hoʻolako ʻia ma ka uea kuʻi a me ka uea puna ma ke ʻano coil a ʻoki ʻia ka lōʻihi.

Inconel 602CA pepa a me ka pā

ʻO ka laulā a hiki i 1500mm a me ka lōʻihi a hiki i 6000mm, Mānoanoa mai 0.1mm a 100mm.

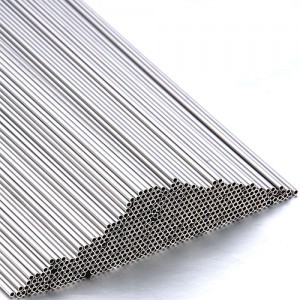

Inconel 602CA paipu ʻole a me ka paipu Welded

Hiki ke hana ʻia ka nui maʻamau a me ka nui i hoʻopili ʻia e mākou me ka hoʻomanawanui liʻiliʻi

Inconel 602CA apo kalaiwa

Forging Ring a i ʻole gasket, hiki ke hoʻopili ʻia ka nui me ka ʻālohilohi a me ka hoʻomanawanui pololei

ʻO Inconel 602CA kāʻei a me ka wili

ʻO ke kūlana palupalu a me ke kūlana paʻakikī me ka ʻili ʻālohilohi AB, ka laulā a hiki i 1000mm

Inconel 602CA Flange

Hiki ke hana ʻia ka nui maʻamau a me ka nui i hana ʻia e mākou me ka hoʻomanawanui pololei

No ke aha ʻo Inconel 602CA?

1. Kūʻē kūʻē i ka oxidation cyclic ma o 2250°F (1232°C)

2.Excellent kiʻekiʻe wela kolo ikaika

3.Resistant i ka carburizing a me ka nitriding kaiapuni

4.Highly kū'ē i ka ulu palaoa ma ka lawelawe

5. ʻO ka hana kiʻekiʻe i ka oxidizing / chloridizing kaiapuni

6.Good kū'ē i ka lepo metala

Inconel 602CA kahua noi:

• Calciners no ka hana minerala

• Hoʻomaʻamaʻa wela i nā muffles a me nā retorts

• Ke hoʻopaʻa ʻia ka mahu kemika

• Nā mea paʻa i ka umu ahi

• Nā pūnaewele kākoʻo hoʻoheheʻe nitric acid

• Mea hana aniani hoohehee

• Nā paipu hoʻomehana uila

• Ka hana ʻana o ka fiber carbon

ʻO Inconel 602CA he kalapona nickel-ferrochrome kiʻekiʻe e loaʻa ana ka nui o ka titanium, titanium, aluminika a me ka honua yttrium. He hana kolo maikaʻi loa ia ma ka wela kiʻekiʻe. ke kū'ē i ke kiʻekiʻe wela, ʻoi loa i ka cyclic environment.At the same time in carbonization, oxidation, chlorination and metala pauda kaiapuni no hoi i maikai kiʻekiʻe temperature.The alloy ua hanaia no ka paomi moku me ka hana ana wela a hiki i 899℃ a me 1150C