Haynes25 kiʻekiʻe wela kūʻokoʻa

Haynes25 kiʻekiʻe wela kūʻokoʻa alloy,

ʻO Haynes25 haku mele, L605, hoʻokō, R30605,

Nā inoa kālepa maʻamau: Haynes 25, AlloyL605, Cobalt L605,GH5605, Udimet L605, UNSR30605

ʻO Haynes 25 (AlloyL605) kahi hopena paʻa i hoʻoikaika ʻia i ka cobalt-chromium-tungsten nickel alloy me ka ikaika kiʻekiʻe kiʻekiʻe a me ke kūpaʻa oxidation maikaʻi loa i 2000°F(1093°C).Hāʻawi ka alloy i ke kūpaʻa maikaʻi i ka sulfidation a me ke kūʻē ʻana i ka ʻaʻahu a me ka galling.Hoʻohana ʻia ʻo Alloy L-605 i nā noi turbine gas e like me nā apo, nā ʻāpana a me nā ʻāpana o ke keʻena puhi ahi (pepa fabrications) a hiki ke hoʻohana ʻia i nā noi umu ahi e like me nā muffles a i ʻole nā liners i nā kiln wela kiʻekiʻe.

ʻO Haynes 25(Alloy L605) Ka Hui Kemika

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 | 19.0-21.0 | 9.0-11.0 | ≦3.0 | 14.0-16.0 | kaulike | 1.0-2.0 | ≦0.4 | ≦0.03 | ≦0.04 |

Haynes 25(Alloy L605) Nā Pono Kino

| ʻO ka mānoanoa (g/cm3) | Lae hehee (℃) | Hiki wela kiko (J/kg·℃) | ʻAiʻa uila (Ω·cm) | ʻO ke kau wela wela (W/m·℃) |

| 9.27 | 1300-1410 | 385 | 88.6×10E-6 | 9.4 |

ʻO Haynes 25 (Alloy L605) Nā Pono Mechanical

Lunamakaainana Tensile Properties, Pepa

| Mahana, °F | 70 | 1200 | 1400 | 1600 | 1800 |

| ʻO ka ikaika ʻoi loa, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Ka ikaika hua, ksi | 69 | 48 | 41 | 36 | 18 |

| Hooloihi, % | 51 | 60 | 42 | 45 | 32 |

ʻO ke koʻikoʻi maʻamau

| Mahana, °F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| 100 hola, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| 1,000 hola, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25 (Alloy L605) Nā Kūlana a me nā kikoʻī

AMS 5537, AMS 5796, EN 2.4964, GE B50A460, UNSR30605,Werkstoff 2.4964

| Bar/Rod | Uea/Welding | Hoʻopaʻa / ʻāwili | Pepa/Pula | Paipu/Tube |

| AMS 5537 | AMS 5796/5797 | AMS 5537 | AMS 5537 | – |

ʻO Haynes 25 (Alloy L605) nā huahana i loaʻa ma Sekonic Metals

Alloy L605 Bar & Kookoo

ʻO nā kaola pōʻai / nā pā pālahalaha / nā kī Hex, Nui Mai 8.0mm-320mm, Hoʻohana ʻia no nā bolts, fastners a me nā ʻāpana ʻokoʻa ʻē aʻe.

Alloy L605 uwea wiliwili

Hoʻolako ʻia ma ka uea kuʻi a me ka uea puna ma ke ʻano coil a ʻoki ʻia ka lōʻihi.

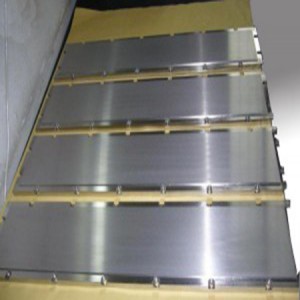

Alloy L605 pepa a me ka pā

ʻO ka laulā a hiki i 1500mm a me ka lōʻihi a hiki i 6000mm, Mānoanoa mai 0.1mm a 100mm.

Alloy L605 Gasket/ apo

Hiki ke hoʻopilikino ʻia ke ana me ka ʻili ʻālohilohi a me ka hoʻomanawanui pololei.

Alloy L605 strip & coil

ʻO ke kūlana palupalu a me ke kūlana paʻakikī me ka ʻili ʻālohilohi AB, ka laulā a hiki i 1000mm

No ke aha ʻo Inconel Haynes 25(Alloy L605) ?

•ʻO ka ikaika wela kiʻekiʻe

•ʻAʻole hiki i ka 1800 ° F

•ʻAʻole kū i ka Galling

•Kūleʻa i nā kaiapuni kai, nā waikona a me nā wai kino

Haynes 25(Alloy L605) kahua noi:

•ʻO nā ʻāpana ʻenekini turbine kinoea e like me nā keʻena puhi ahi a me nā mea puhi ahi

•Piʻi kinipōpō wela kiʻekiʻe a me nā heihei amo

•Punawai

•Puuwai puuwai

ʻO Haynes 25 alloy he pahu cobalt-nickel-cr-w me - ka ikaika wela kiʻekiʻe a me ka -1800 ° F (980 ° C) kaiapuni hoʻonaʻauao, ka lōʻihi o ka hoʻolaha ʻana, a me ka - vulcanization resistance. Ua hoʻohana ʻia no ka hoʻolei ʻana i nā ʻāpana. ʻO nā hiʻohiʻona maikaʻi ʻē aʻe e pili ana i ke kūʻē ʻana i ka ʻaʻahu a me nā waimaka ma nā metala. : Ua kapa ʻia ʻo Haynes 25 Alloy ʻo R30605. Bars, bars, Wires and Forgings: AMS 5759 (bars, apo and forgings), Sheets, sheets and strips: AMS 5537 (Sheets, strips and sheets) Others: AMS 5796 (Wire) and AMS 5797 (Hoʻopili ʻia nā electrodes welding)