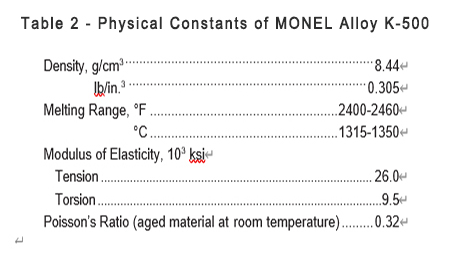

ʻO MONEL Alloy K-500 (UNS N05500 / WR2.4375) he nickel-copper alloy e hui pū ana i nā mea maikaʻi o ke kūpaʻa corrosion maikaʻi loa me ka ikaika a me ka paʻakikī o MONEL alloy 400. Ua hoʻohui ʻia ka alumini a me ka titanium i ka base nickel-copper a hoʻomehana ʻia. ma lalo o nā kūlana i hoʻopaʻa ʻia e precipitate submicroscopic Ni3(Ti, AI) particles a puni ka nickel-copper base, pēlā e hoʻomaikaʻi ai i ka matrix hana.ʻO ka hoʻohana ʻana i ka hana wela e hoʻokō ai i ka hopena o ka ua i kapa ʻia ʻo aging hardening a aging.

ʻO nā noi maʻamau o nā huahana MONEL alloy K-500 he kaulahao a me nā kaula kaula a me nā pūnāwai.

Nā lawelawe moana: Pump a me nā hui valve,

Lapaʻau kemika: ka hana ʻana i ka pulp i ka hana ʻana i ka pepa no nā lau o ke kauka a me nā ʻōpala;

ʻO ka luawai ʻaila a me nā mea kani, ka pahu pahū a me ka impeller, hale non-magnetic, hoʻokiʻekiʻe palekana a me ka valve aila a me ka hana kinoea maoli;A me nā mea ʻike a me nā mea uila ʻē aʻe.

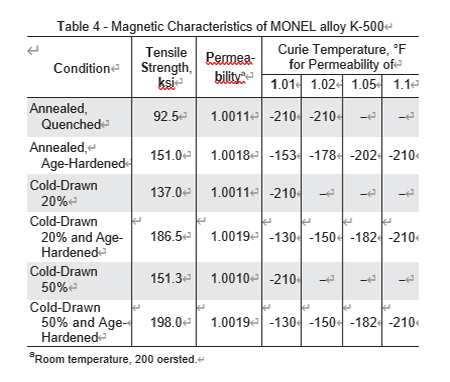

ʻO kekahi o nā waiwai o ka huila Monel K500, ʻo ia ka mea ʻaʻole magnetic, ʻoiai ma nā haʻahaʻa haʻahaʻa.Eia nō naʻe, hiki ke hana i kahi papa magnetic ma ka ʻili o ka mea i ka wā e hana ai.Hiki ke koho ʻia ka alumini a me ke keleawe i ka wā hoʻomehana, e waiho ana i kahi kiʻiʻoniʻoni nickel magnetic ma waho o ka pepa.Hoʻopuka nui ʻia kēia hopena ma ka uwea lahilahi a i ʻole ka ʻili me ka ratio kiʻekiʻe o ka ʻili a me ke kaumaha.Wehe ʻia ke kiʻi magnetic ma ka pickling a i ʻole ka leaching acid bright e hoʻihoʻi i nā waiwai non-magnetic o ka mea.Ua hoʻohana ʻia ka hui ʻana o ka haʻahaʻa haʻahaʻa, ka ikaika kiʻekiʻe, a me ke kūpaʻa corrosion maikaʻi loa i nā noi he nui, ʻoi aku ka maikaʻi o nā lako ana a me nā mea uila.

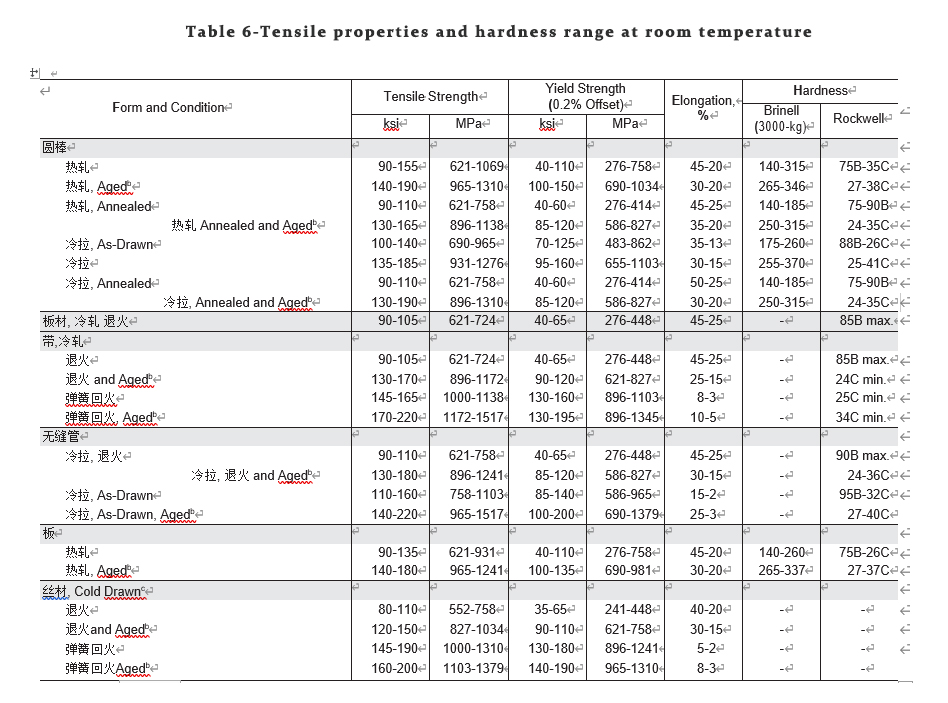

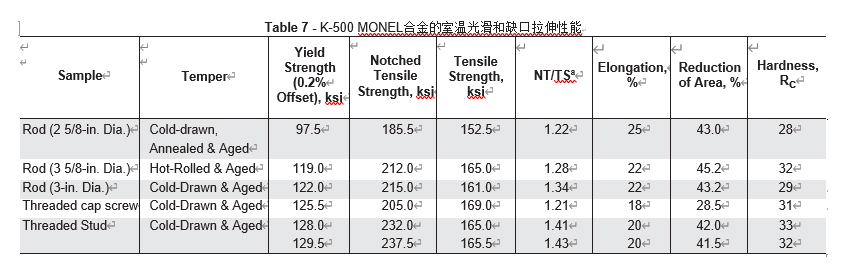

Ua ʻike ʻia ʻo Monel alloy K-500 he kūlana paʻa maikaʻi loa i ka hōʻike hōʻike lōʻihi a me ka hoʻāʻo ʻana.ʻO kēia waiwai o ka'āpana e hiki ai ke hoʻohanaʻia i nā mea hana kiʻekiʻe e like me nā gyros.Hōʻike ʻia ka laulā inoa o nā waiwai tensile a me ka paʻakikī i ka wela lumi ma ka Papa 6. Hōʻike ʻia nā pilina ma waena o nā waiwai tensile a me ka paʻakikī no nā kaola a me nā forgings ma Fig.4 a me 5, a ʻike ʻia nā pilina like ʻole no nā lau a me nā ʻili ma ke Kiʻi 6. Hoʻohālikelike ka Papa 7 i ka hana notch o nā mea hoʻohālike maʻalahi.Hōʻike ʻia ka manawa pōkole a me ke kiʻekiʻe kiʻekiʻe o ka tensile tensile o K500 alloy bars ma lalo o nā kūlana like ʻole ma ke kiʻi ma lalo nei.Ua hoʻāʻo ʻia nā koʻokoʻo ʻōwili wela i ka wikiwiki o 0.016 iniha/min ma o ka ikaika hua a me 0.026 iniha/min mai laila e haki.Ua hoʻāʻo ʻia nā mea kikoʻī i huki ʻia i ka ikaika o ka 0.00075 inches / min, a ukali ʻia e 0.075 inches / min.

K-500 Monel alloy he haʻahaʻa haʻahaʻa hana maikaʻi loa.Hoʻonui ka ikaika tensile a me ka hoʻoulu ʻana me ka emi ʻana o ka mahana, ʻoiai ʻaʻole i hoʻopilikia ʻia ka plasticity a me ka paʻakikī.ʻOiai ma nā mahana haʻahaʻa e like me ka hydrogen wai, ʻaʻole hiki ke hoʻololi mai ka paʻakikī a hiki i ka palupalu.No laila, ua kūpono ka alloy no nā noi haʻahaʻa haʻahaʻa.Hōʻike ʻia ka hana o K-500 alloy base metala a me ka pepa welded ma -423°F.Inā hoʻokō ʻia ka hana ʻelemakule ma hope o ka welding annealing material, hiki ke loaʻa ka weld me ka ikaika o ka metala kumu paʻakikī ʻelemakule me ka ʻole o ka pohō nui o ka ductility.Pono e ʻalo ʻia ke kuʻi ʻana o nā mea i hoʻopaʻa ʻia i ka makahiki no ka mea ua hoʻemi nui ʻia ko lākou ductility.

Ua koho ʻia ʻo MONEL alloy K-500 e like me UNS N05500 a me Werkstoff NR.2.4375.Aia ia ma ka NACEMR-01-75 Oil and Gas Services.Loaʻa ka Alloy K-500 ma kahi ākea o nā ʻano wili maʻamau e like me ka tube, tube, plate, strip, plate, round bar, flat bar, forgings, hexagon and wire.Papa, Pepa a me ka Strip -BS3072NA18(Pula a me ka strip),BS3073NA18(Strip),QQ-N-286(Papa, Pepa a me ka Strip),DIN 17750(Papa, Pepa a me ka Strip), ISO 6208(Pepa, Pepa a me ka Strip) Nā Paʻa, Nā Paʻa, Nā Uea a me nā Paʻi -BS3075NA18 (Uea), BS3076NA18 (Rod a me ke koʻokoʻo), ASTM B 865 (Rod a me ke koʻokoʻo), DIN 17752 (Rod a me ke koʻokoʻo), DIN 17753 (Wire), DIN 17754 (Forgings), QQ -N-286(Rod, Rod, Wire and Forgings), SAE AMS 4676(Rods and rods), ASME Code Case 1192(Rods and rods),ISO 9723(rods),ISO 9724(Wire),ISO9725(Forgings) Tubes a me nā Tubes -BS3074NA18(Nā paipu ʻole a me nā paipu), DIN 17751 (Nā paipu a me nā paipu) ʻO nā huahana ʻē aʻe -DIN 17743 (Kemimi Hoʻohui), SAE AMS 4676 (Kemimi hoʻohui), QQ-N-286 (Kemimi hoʻohui)

Ka manawa hoʻouna: Sep-20-2022