AMS ASME ASTM no nā mea hoʻokele inconel625 alloy

AMS ASME ASTM no nā mea hoʻokele inconel625 alloy,

625 Alloy,Inconel 625 Bars ,Inconel 625 Rods,Inconel 625 pepa ,Inconel 625 pā,Inconel 625 strip,Inconel 625 coil,

Nā inoa kālepa maʻamau: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

ʻO Inconel Alloy 625 kahi mea non-magnetic, corrosion a me ka oxidation resistant, nickel-chromium alloy.ʻO ka ikaika kiʻekiʻe o Inconel 625 ka hopena o ka hui paʻakikī o ka molybdenum a me ka niobium ma ka nickel chromium base o ka alloy.Loaʻa i ka Inconel 625 ke kū'ē nui i kahi ākea o nā kaiapuni corrosive koʻikoʻi koʻikoʻi me nā hopena wela kiʻekiʻe e like me ka oxidation a me ka carburization.ʻO kona ikaika koʻikoʻi a paʻakikī i nā pae wela mai nā mahana cryogenic a hiki i ka wela kiʻekiʻe a hiki i 2000 ° F (1093 ° C) i loaʻa mua mai nā hopena hopena paʻa o nā metala refractory Columbium a me ka molybdenum i loko o ka nickel-chromium matrix.

Inconel 625 Huina Kemika

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Max. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Na Waiwai Kino

| ʻO ka mānoanoa | 8.4 g/cm³ |

| Lae hehee | 1290-1350 ℃

|

Inconel 625 Nā Pono Mechanical maʻamau

| Kūlana | Ka ikaika tensile Rm N/mm² | Hua ikaika Rp 0. 2N/mm² | ʻO ka lōʻihi E like me % | ʻO Brinell paʻakikī HB |

| Lapaʻau hoʻonā | 827 | 414 | 30 | ≤220 |

Inconel 625 Nā Kūlana a me nā kikoʻī

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE-3MR01

UNS N06625, Werkstoff 2.4856

| Uea | Pepa | Kaʻi | Rod | Paipu | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Paipu Seamless | Paipu Weled |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

ʻO Inconel 625 nā huahana i loaʻa ma Sekonic Metals

Inconel 625 Bar & Kookoo

ʻO nā kaola pōʻai / nā pā pālahalaha / nā kī Hex, Nui Mai 8.0mm-320mm, Hoʻohana ʻia no nā bolts, fastners a me nā ʻāpana ʻokoʻa ʻē aʻe.

Inconel 625 welding wire

Hoʻolako ʻia ma ka uea kuʻi a me ka uea puna ma ke ʻano coil a ʻoki ʻia ka lōʻihi.

Inconel 625 pepa a me ka pā

ʻO ka laulā a hiki i 1500mm a me ka lōʻihi a hiki i 6000mm, Mānoanoa mai 0.1mm a 100mm.

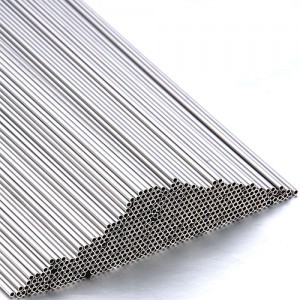

Inconel 625 paipu ʻole a me ka paipu Welded

Hiki ke hana ʻia ka nui maʻamau a me ka nui i hoʻopili ʻia e mākou me ka hoʻomanawanui liʻiliʻi

Inconel 625 strip & coil

ʻO ke kūlana palupalu a me ke kūlana paʻakikī me ka ʻili ʻālohilohi AB, ka laulā a hiki i 1000mm

Inconel 625 mau mea paa

Alloy 625 hiki iā mākou ke hāʻawi i nā bolts, Nuts a me nā mea paʻa ʻē aʻe e like me nā koi o nā mea kūʻai aku

Nā hiʻohiʻona o Inconel 625:

1.High creep-rupture ikaika

2.Oxidation kū'ē i 1800 ° F

3.Good luhi kū'ē

4.Excellent weldability

5. Kū'ē kū'ē i ka chloride pitting a me ka crevice corrosion

6. Immune i ka chloride ion stress corrosion māwae

7. Paʻa i ka wai kai ma lalo o nā kūlana kahe a me ke kūpaʻa a ma lalo o ka hoʻoheheʻe ʻana

Inconel 625 kahua noi:

•Nā ʻōnaehana hoʻoheheʻe mokulele

•Pūnaehana hoʻopau ʻenekini jet

•Pūnaehana hoʻohuli ʻenekini

•Bellows a me nā hono hoʻonui

•ʻO nā apo puʻupuʻu turbine

•ʻO nā pahu ahi

•Nā mea wai kai

•ʻO nā lako kaʻina hana kemika e lawelawe ana i nā ʻakika hui pū ʻia me ka hoʻokahe a me ka hoʻohaʻahaʻa.

ʻO kā mākou hui huahana Forms

Bara & Kookoo

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Tube Seamless & Tube Welded

ʻO nā paipu nikela/Titanium Alloy, U-piko / paipu hoʻololi wela

Bolt & Nati

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Pepa & Papa

Hastelloy/Inconel/ Incoloy/ Cobalt/Tianium

Kaha & Foil

Hastelloy/Inconel/invar/ soft magnetic Alloys ect

Punawai Kiekie

Inconel 718/Inconel x750/ Nimonic 80A

Uea & wiliwili

ʻO ka uea Cobalt Alloy, Nickel alloy wire, Tianium Alloy wire

Nā Flange Alloy Kūikawā

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Kau Aila Paipu

Inconel x750/ Inconel 718 / Monel 400 ect

ʻO nā mea hoʻohui nikela

Na mea wiliwili

Nā Alloy Cobalt

Na Kuleana Kuikawa

ʻO nā huila pololei

ʻO nā huila Titanium

Makemake ʻoe e aʻo hou a loaʻa paha kahi ʻōlelo?

E kiʻi mai

He aha ka mea i hana ʻia me 625 alloy?ʻO kahi huila nickel-based me ke kiʻekiʻe Ni – Cr – Mo.

Huina kemika o Alloy 625: Chromium (Cr)20.0-23.0, Hao (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulfur (S)< 0.015, Cobalt (Co)< 1.0, (Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, Kalapona (C)< 0.01.

ʻO 625 Alloy nā hiʻohiʻona maikaʻi loa o ka oxidation a me ka pale ʻana i ka corrosion, ka ikaika maikaʻi a me ka paʻakikī, ke kūpaʻa luhi maikaʻi, ke kūlana kiʻekiʻe, a me ka weldability maikaʻi loa.Hiki iā ia ke mālama i kona ikaika a paʻakikī ma nā wahi a pau mai nā mahana haʻahaʻa a hiki i 2000 ° F.Ma muli o ka paʻakikī paʻakikī o ka alloy 625, hiki i ka nui o ke anuanu ke koi aku i ka annealing i ke kaʻina hana anu.Hoʻohana pinepine ʻia ka alloy i nā mīkini jet a me nā noi aerospace ʻē aʻe.